|

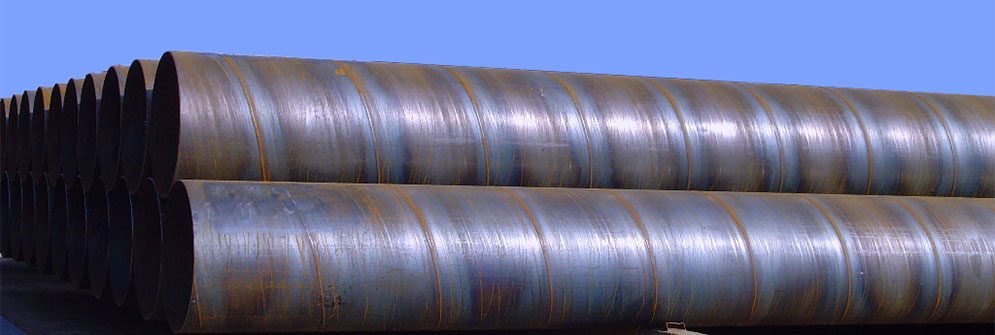

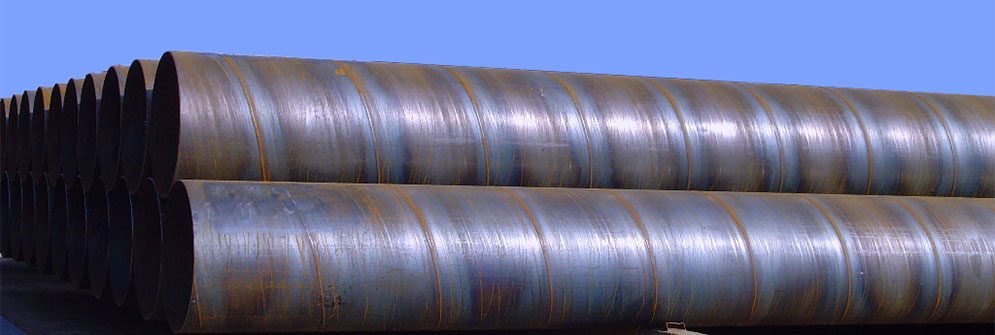

We execute various types of coating for preventing corrosion on pipe’s surface both internal as well as external as per IS, ISO and AWWA standards, which protects steel pipes against corrosion hence increases the pipe’s life.

Corrosion is the chemical disintegration of a substance into its component atoms due to its reaction with the environment. It is the degradation of metals commonly referred to as rust. Corrosion of metallic structures causes huge economic impacts around the world.

Various anti corrosion methods and techniques are devised and used that effectively minimize the impact of corrosion.

TYPES OF COATING:

We are engaged in providing high performance Anti Corrosive Coatings such as:- |